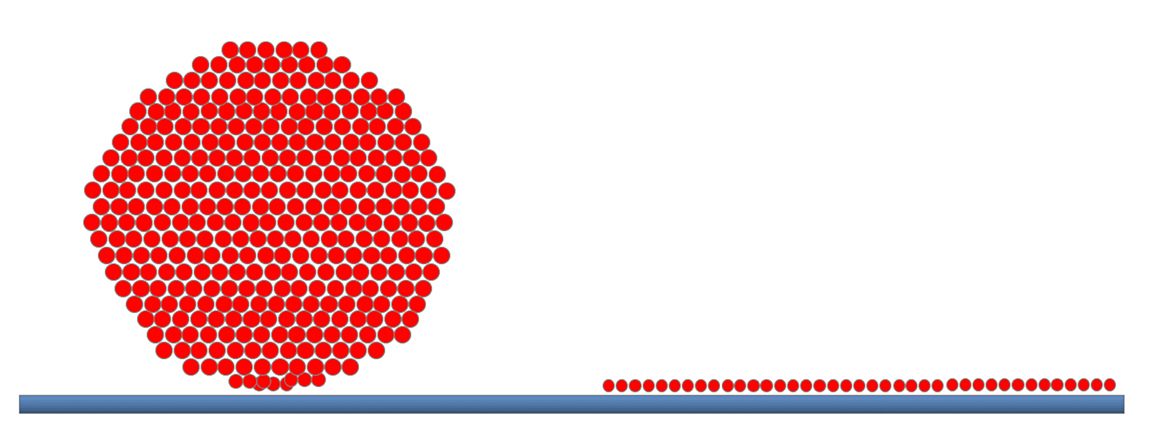

From a technical prospective LMI™ is designed on a theoretical model of a unimolecular complex (capable of entertaining a unimolecular reaction) of a metal ion in its stable oxidation state hosted in an envelope of ligands that can provide a coordination number of 4 to 6 with the choice of a donor solvent without the restriction of dominant metal-ligand interaction.

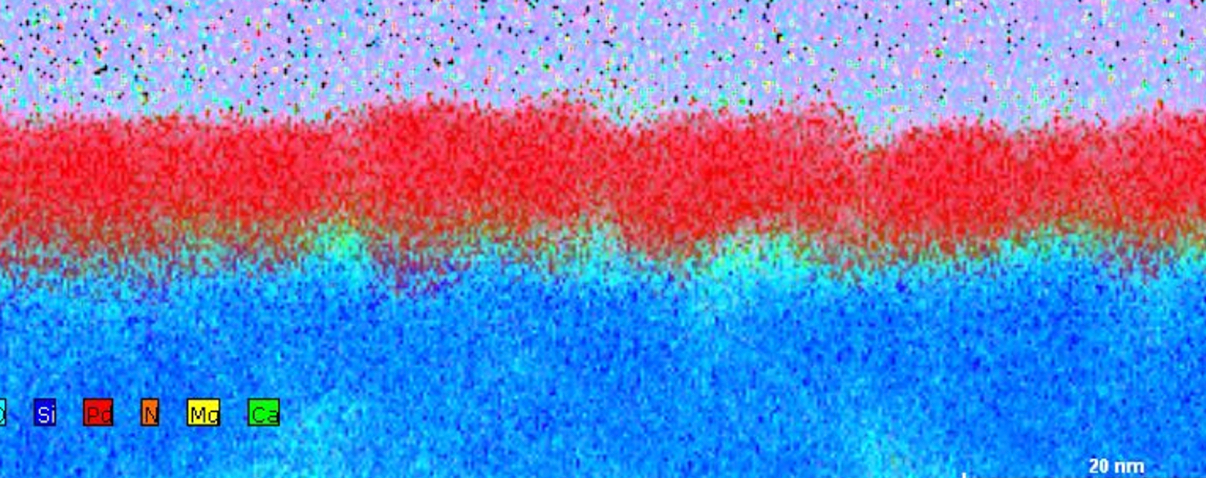

Thermodynamic stability in the chromophore of the metal ion is achieved by competitive coordination with specific prejudice to palladiophilic ligands. These properties allow LMI™ to layer on single metal atoms until a uniform yet thin seed layer if formed. In most cases, this layer is non conductive.